By loading the video, you agree to YouTube's privacy policy.

Learn more

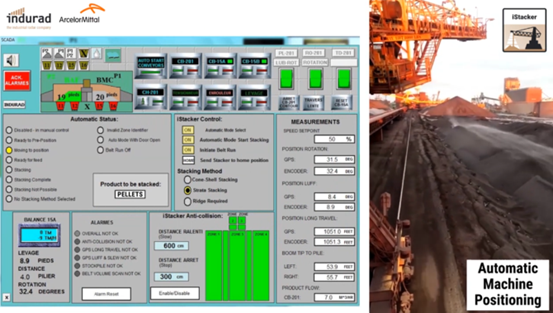

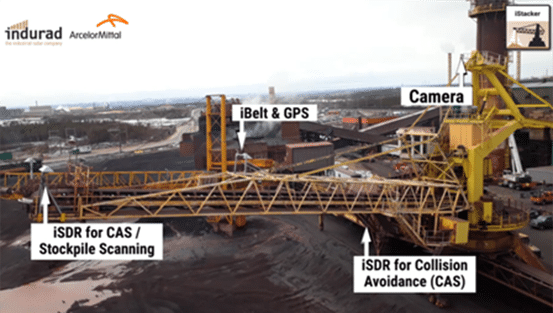

Safety & Efficiency

Glencore Nickel: A vision of Safety and Precision

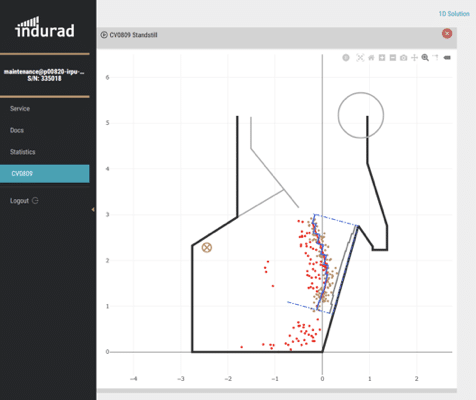

A dust suppression system impaires visitoin of the human operator unloading vessels at at Port of Quebec. Indurad “restores” the operator’s vision using it’s 3D radar technology.